|

|

| |

|

Click to Enlarge

Click to Enlarge |

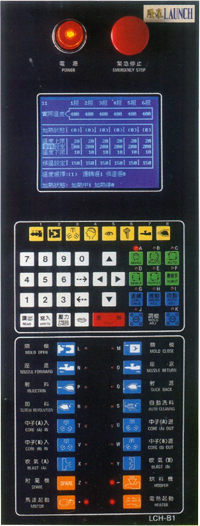

Indroduction

- English and Chinese language interchanges select

function to make simply under standing for foreign workers.

- Auto mold adjustment devices is according to the

mold clamping force and automatic setting mold clamping

high and low pressure and position.

- The logical computer also can automatic setting mold

clamping super low pressure system to protect mold damaged.

- Silicon auto spraying function can help to enhance

the degree of mechanical automation.

- Precise core pull with threading and positioning

function.

- Multi air blow function to select.

- Product quality control and conveyer permanent delivery

function.

- Product packing counter calculation function.

- One week preset time control ON/OFF function for

Hopper Dryer, Barrel and Attachment equipment function.

- Heater temperature is control by P.I.D system and

can setting upper and lower range point control function

and temperature keep warm function.

- Five stage injection speed and pressure , five stage

holding speed and pressure and three stage screw charging

speed function.

- Injection leakage and injection shortage checking

function.

- Holding pressure charge by ( time, position, mold

inner pressure, injection cylinder inner pressure and

pressure inspection gauge) with multi selection type.

- Screen rotation speed display and counted.

- Injection screen auto purge function.

- Special function key can increase injection parts

weight.

- Suck back first before screw charging function.

- Injection screw cold start prevention function to

protect injection screw damaged or broken.

- Over 100 sets of mold data memory function with key

in mold name list.

- With workers statistical efficiency record.

- Defect product checking function with robotic arm

separate select function.

- Self diagnosing checking function to boost trouble

shooting and increase efficiency.

- Product quality control and inspection report.

- Oil temperature over heat alarm function.

|

|

|