| The plastic injection

temperature is usually high. Injecting with air

will burn the plastic since the oxygen in the

air is flammable, which would be more obvious

for transparent plastic parts. Therefore, injection

molding machine uses nitrogen since it is not

flammable.

Accumulator assist injection molding machine

must be installed with a set of gas assist injection

equipment, including:

- Nitrogen producing machine or nitrogen bottles

(grade nitrogen purity to 99%).

- High-pressure nitrogen compressor and for

a little quantity production can use pressurized

cylinder mode.

- High-pressure gas cylinders (for bigger quantity

production use).

- Gas assisted controller (it have single loop

circuit and multi loop circuit two type).

Accumulator assist injection molding machine

is specialized in avoiding sink mark, warping,

flow line mark, reduce product weight (up to 50%

depending on product condition), product cost,

molding cycling time (up to 30% depending on product

condition), increasing production efficiency,

and internal force.

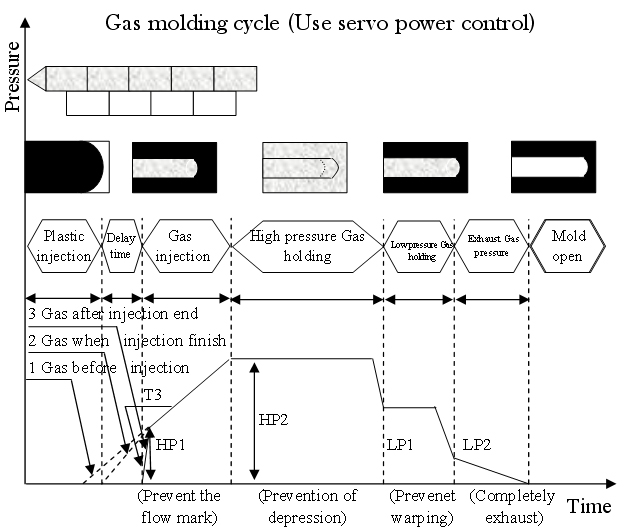

Gas-assisted injection molding flow chart:

The above diagram explains that the nitrogen can

be injected when either the injection complete

or incomplete. The machine uses gas assist injection

controller unit to control nitrogen pressure and

time to achieve the pressure holding performance,

then open the mold to take out the product after

gas went out.

Accumulator assist injection molding machine

has been used to make television frame, car handle,

steering wheel, and home products like chair,

table, handle, clothe hanger..., etc. |